Another opportunity for increasing agility and reducing waste is in the area of operations. While it is good to expand the capacity for revenue, it’s also good to reduce operations costs wherever possible, which can be a simple way to increase a company’s bottom line.

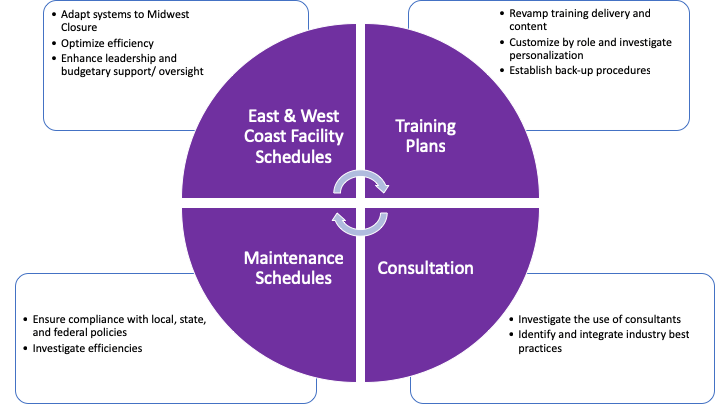

Figure 1 shows the areas within which there’s an opportunity reduce waste and increase efficiencies in a way that supports employee satisfaction.

Figure 1. Key ingredients of the Sun Basket operational plan.

Of note are the categories of East & West Cost Facility Schedules and Maintenance Schedules. In the first case, some time and attention should be invested in making sure the coasts are running efficiently since the Midwest location has been closed. There may be systems that need updating to reduce strain on databases or other business intelligence-related systems. Additionally, by implementing the leadership training suggested in the previous post, employees are expected to become more productive and efficient because they’ll care more about their environment and feel more of an affinity to management.

As for maintenance schedules, its critically important that local, state, and federal policies are followed thoroughly. This is not just because of the fees that can be charged to Sun Basket for compliance failures. But it’s also because not conducting business in line with these policies creates the opportunity for inefficiency, which also cuts into profit.

Post #10 in this series explores a cash flow analysis.